Sani Sensitive products have been produced for years with a design that is proven to be friendly for the skin and are designed with respect to the environment. More specifically

- They are produced in MEGA’s factory, that has obtained the Green Certificate which confirms that the electricity consumed comes from 100% green energy sources.

- MEGA received the international certification Zero Waste to Landfill at “Platinum” level, as in 2022 its production unit achieved 99,8% recycling and Energy Recovery.

The fluff pulp used for the production of Sani Sensitive Pants, Sani Sensitive bedpads as well as Sani Lady and MEN pads consists of materials from responsible resources, such as Forest Stewardship Council FSC® certified pulp, thus limiting the effects on the environment.

Sani Sensitive products are produced with ELEMENTAL CHLORINE FREE Paper pulp (ECF) and use SAP (Super Absorbent Polymer), an over-all technology that gives higher absorbency with less amount of synthetic grain used.

At MEGA we make every effort to reduce energy consumption, thereby contributing to the reduction of our carbon footprint. MEGA completed in 2023 one of the largest photovoltaic system installation projects in our country. The company also utilizes solar energy for the production of its products. The investment corresponds to systems with a total power of 3MWP, on 25,000 square meters of the roof of the company’s facilities in Acharnes.

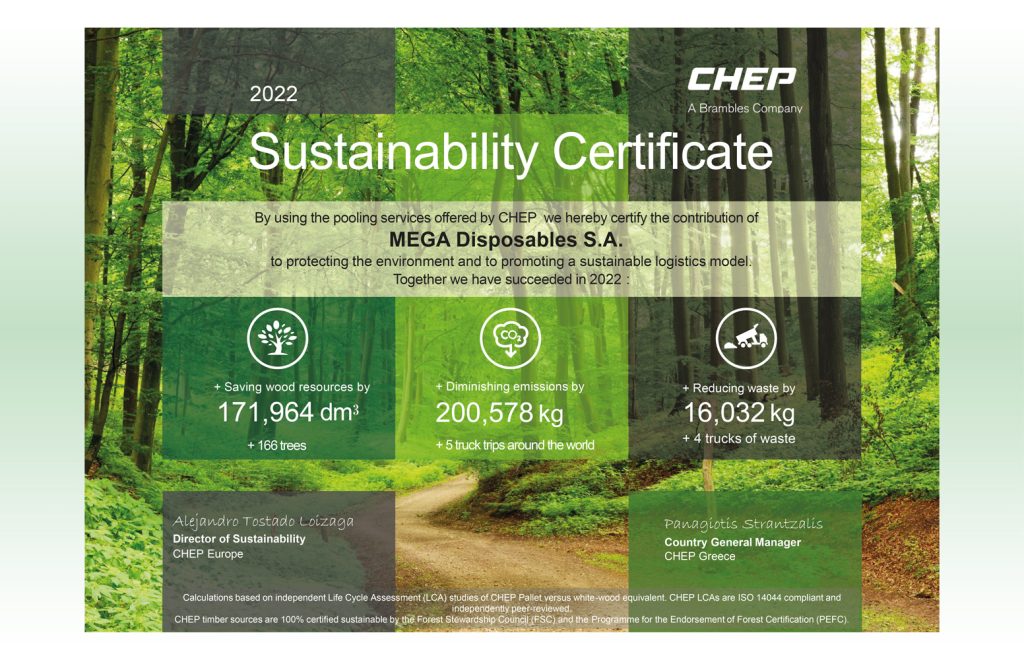

MEGA has received the sustainability certificate for the protection of the environment and the promotion of a sustainable supply chain model through its participation in the Pooling system of CHEP, contributing to reducing timber, carbon dioxide emissions and waste emissions.

Sani Sensitive packages are 100% recyclable. MEGA as a producer participates since 2003 in an Alternative Management System (Hellenic Recovery Recycling Corporation, HERRCO) and contributes financially to the recycling of the packaging.

All cartons of Sani Sensitive consist of up to 100% recycled material.

Over the past 2 years, MEGA incorporates sufficient amount of raw materials enforcing the circular economy into its product’s packaging, promoting at the same time the low-carbon economy and the reduction of the natural resources overexploitation. The company constantly collaborating with certified suppliers and recyclers, whilst is committed to escalate these efforts by the year 2050.